トピックスTopics

-

「2026ほっかほかキャンペーン」開催について

2025.11.25 期間中、ニューレジストン製品をご購入いただくと日清食品ミニーズを進呈します。

-

「安全グラインダ180」・「シェル ジェイドタイプ」・「ゼータカット」大径サイズ 新製品 発売のお知らせ

2025.06.10 安全性を高める2つの新製品及びゼータカット大径サイズを発売いたします!

-

『ニューレジとくとく倶楽部会員サービスのリニューアル × ニューレジストン(株)公式LINEの開設』のご案内

2025.2.3 「ニューレジとくとく倶楽部」ポイント会員サービスは、ニューレジストン㈱公式LINEへ移行しリニューアルスタートします!

-

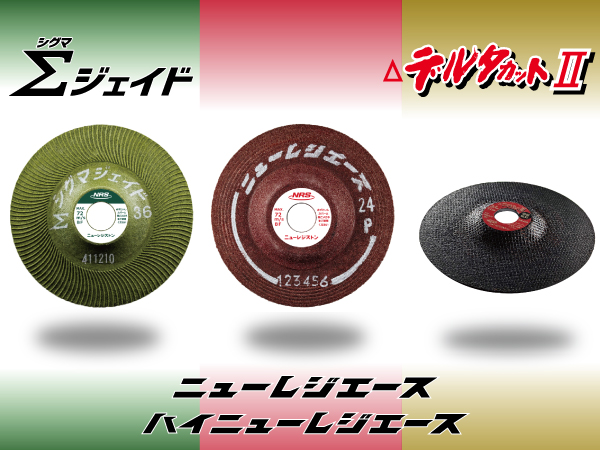

「Σ(シグマ)ジェイド」・「ニューレジエース」・「ハイニューレジエース」・「デルタカットⅡ」新発売のお知らせ

2024.12.13 従来品より性能UPした4つの新製品を発売いたします!

-

「NRS超硬バー」特注品製作サービス開始のお知らせ

2024.11.29 「NRS超硬バー」特注品製作サービス開始しました。

-

安全データシート(SDS)のダウンロードについて

各製品のSDS(安全データシート)をPDFダウンロードいただけます。

新着情報News

-

2025.12.09企業情報

-

2025.11.25お得情報

-

2025.11.04製品

-

2025.10.27製品

-

2025.08.01とくとく倶楽部

-

2025.11.04製品

-

2025.10.27製品

-

2025.06.27製品

-

2025.06.10製品

-

2025.03.21製品

-

2025.12.09企業情報

-

2025.07.29企業情報

-

2025.06.20企業情報

-

2025.05.07企業情報

-

2025.04.22企業情報

-

2025.11.25お得情報

-

2025.07.22お得情報

-

2024.11.28お得情報

-

2024.07.24お得情報

-

2024.02.02お得情報

-

2025.08.01とくとく倶楽部

-

2025.02.03とくとく倶楽部

-

2021.12.20とくとく倶楽部

-

2021.07.01とくとく倶楽部

-

2021.07.01とくとく倶楽部

Copyright (c) NEWREGISTON Co., Ltd. All rights reserved.